Contact your sales representative and clerk

Product datasheets and safety data sheets

Overview of product stock availability

Educational materials

News about industrial seals

Information on new products and services

Exclusive hints and tips

Describe us the parameters of your application. We will recommend the optimal product for you.

We will call you at your chosen time and advise you on what you need.

Our sales and technical representative will come to your company for a personal consultation.

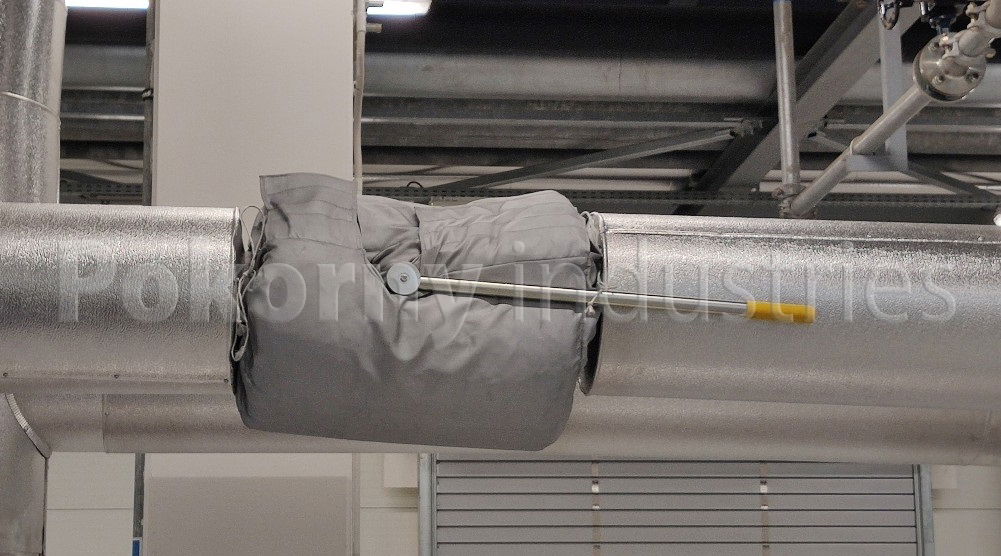

The reduction of heat loss from technological equipment that is difficult to insulate by conventional insulation methods (valves, valves, flanges, etc.) can be achieved by using removable thermal insulation linings. These sleeves are able to reduce energy losses by up to 80% and provide significant financial savings to the operation.

Thermal insulation sleeves are made to measure according to the dimensions of the specific equipment. The advantage of the sleeves is very easy handling, which is facilitated by fastening with Velcro, laces or hooks. The operator thus does not need any special equipment for fitting or removal.

The high-tech fibreglass-based materials of which the covers are made do not break even with multiple handling and maintain stable thermal insulation properties throughout. These materials are water resistant, flammable and can withstand highly corrosive chemicals. The materials also do not induce static electricity (R˂ 10 -⁶Ω) and are therefore suitable for explosion hazardous environments (EX). Heat transfer requirements of the equipment can also be taken into account for the material.

| Without insulation | With insulation |

|---|---|

| Surface temperature 400 °C | Surface temperature 50 °C |

| Heat loss 24 MWh/year | Heat loss 1.9 MWh/year |

| Losses 8 640 CZK/year | Losses 684 CZK/year |

With a price of 5 400 CZK and a price of 1 MWh of natural gas of 360 CZK, the savings are 7 956 CZK per year. The return on investment is 8 months.

Pokorny Industries Partnership in quality

© Pokorny industries s.r.o. 2024 - all rights reserved

Made by servisdesign